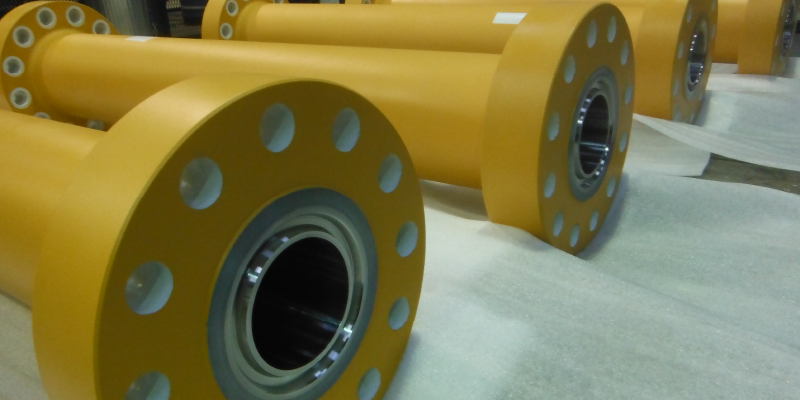

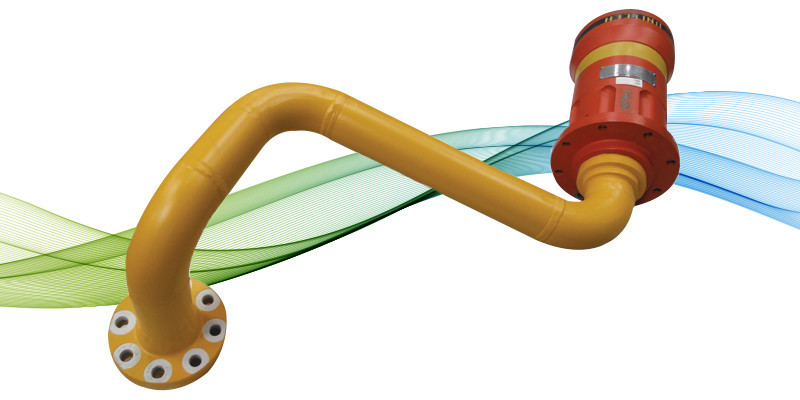

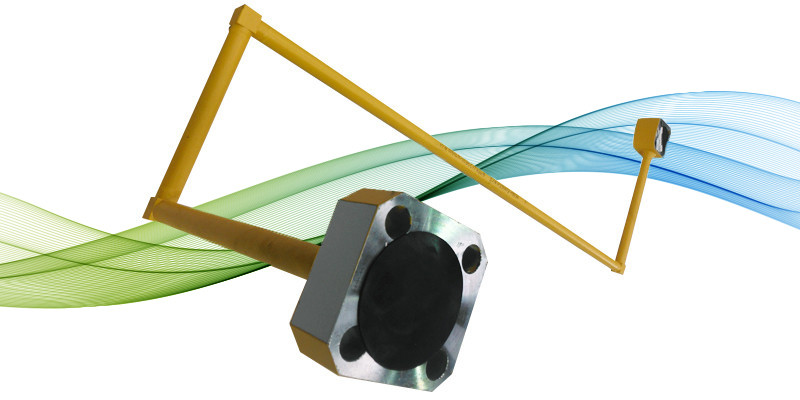

Subsea Spool Manufacture

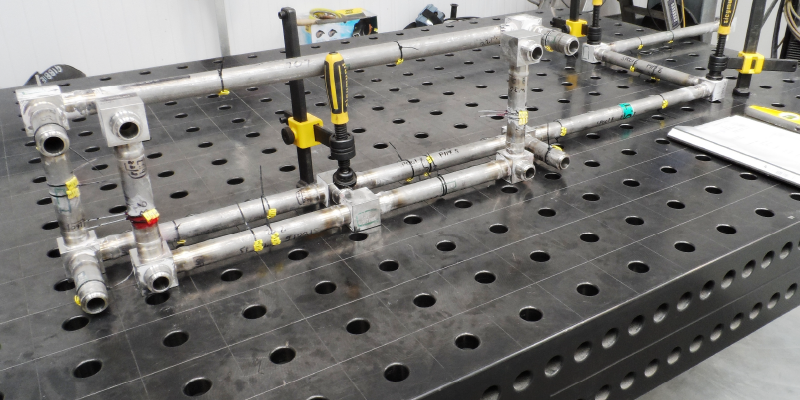

Our business model has been honed over many years to support the manufacture of specialised subsea flow spool, crossover and chemical injection spool systems.

L&N Scotland’s purpose built facility houses the latest advancements in specialised manufacturing and inspection equipment. Our highly experienced team encompasses engineering trades and specialist support to ensure the highest levels of quality, and that maximum value is added to our product.

Carrying a large stock of raw materials in grades common to Subsea applications, L&N Scotland have the ability to significantly reduce lead times, and the inherent costs associated with purchasing and testing specialised material grades on a project specific basis.

Key Features